FMEA

Gezieltes Risikomanagement von Anfang an

Risiken im Voraus zu minimieren oder sogar auszuschließen, bedeutet in der Produktentwicklung und Produktion, wertvolle Zeit und Kosten zu sparen. Um dieses Ziel zu erreichen, nutzen wir die Fehlermöglichkeits- und einflussanalyse – kurz FMEA. Mit der FMEA es möglich, in den einzelnen Phasen der Produduktentstehung Fehler zu verhindern und Risiken zu minimieren. Verknüpft mit anderen präventiven Qualitätsmethoden, wie zum Beispiel dem Toleranzmanagement, erschließen sich weitreichende Möglichkeiten der Produkt- und Prozessoptimierung.

FMEA von A bis Z

Wir unterstützen Sie bei Ihrer FMEA. Völlig unabhängig davon, ob eine schon bestehende FMEA aktualisiert oder eine FMEA neu aufgesetzt werden soll. Wir können Sie begleiten von den ersten Schritten an bis zum finalen Audit – sofern notwendig.

Expertise mit Nutzen

Für die Durchführung einer System-FMEA, Design-FMEA oder Prozess-FMEA nutzen wir die Software APIS IQ-FMEA sowie PLATO SCIO™. Neben der Strukturierung, der Dateneingabe und Pflege sowie der Risikoanalyse zählt auch die Moderation der erforderlichen Workshops zu unseren Stärken. Hierzu kann auch die Präsentation bei Ihrem Auftraggeber gehören, zum Beispiel im Rahmen eines Kundenaudits. Und falls Sie beabsichtigen, die FMEA zukünftig selbstständig durchzuführen, unterstützen wir Sie mit „Training on the job“-Projekten, damit Sie so schnell wie möglich dieses Ziel erreichen können.

Das Know-how unserer Ingenieure resultiert aus jahrelanger Erfahrung in den verschiedensten Branchen und Disziplinen sowie stetiger Weiterbildung und permanentem Ausbau unseres Dienstleistungsangebots. Nutzen Sie diese Potenziale, um Ihren Kapazitätsbedarf flexibel sowohl kurz- als auch langfristig zu decken. Diese Dienstleistung können wir Ihnen auch in Form einer Arbeitnehmerüberlassung (ANÜ) anbieten.

![]() APIS IQ-FMEA

APIS IQ-FMEA

![]() PLATO SCIO™-FMEA

PLATO SCIO™-FMEA

![]() Ihre eigenen Templates (z.B. Excel)

Ihre eigenen Templates (z.B. Excel)

![]() Erfahrende Moderatoren

Erfahrende Moderatoren

![]() Kurze Reaktionszeiten

Kurze Reaktionszeiten

![]() Know-how aus verschiedenen Branchen und Disziplinen

Know-how aus verschiedenen Branchen und Disziplinen

![]() Zusatzqualifikationen im Haus

Zusatzqualifikationen im Haus

- Toleranzmanagement

- 3D-Messtechnik (taktil, optisch)

- BMW Group

- Continental Automotive GmbH

- Hübner GmbH & Co. KG

- MT Technologies GmbH

- VolaPlast Werner Hoppach KG

- Xperion components Gmbh & Co.KG

- u.v.m.

Ihr Ansprechpartner im Bereich FMEA ist

Herr Dipl.-Ing. Mirco Simunovic

Das sagen unsere Kunden

„Zusammen mit unserem langjährigen Engineering-Partner casim konnten wir ein innovatives System entwickeln, welches unsere führende Marktposition auch in Zukunft sichert.“

„Wenn es um die volle Wertschöpfungskette geht, bietet unser Engineering-Partner casim alles – von der Idee über die begleitende Berechnung bis hin zur fertigen Konstruktion.“

Oder schreiben Sie uns jetzt eine Nachricht:

FMEA

Zum Thema Fehlermöglichkeits- und einflussanalyse (FMEA) finden Sie hier unsere Inhalte, nutzen Sie hierfür auch gerne unser Inhaltsverzeichnis mit Schnellinks:

2. Die richtige Vorbereitung einer FMEA

4. Die strukturierte Vorgehensweise (Produkt FMEA)

4.2.1 Die Fehlfunktionsanalyse

5. Ergänzendes zur Prozess FMEA

1. Ziele der FMEA

Die FMEA (Prozess FMEA, Design FMEA) reiht sich in eine Vielzahl von präventiven Methoden zur Qualitätssicherung ein. Wie die anderen Methoden auch, ist sie entwicklungsbegleitend und wird somit fortwährend betrieben, bis über der SOP (Start of Production) hinaus. Primäres Ziel der FMEA ist, potenzielle Fehler so früh wie möglich zu erkennen, um sie so vermeiden zu können. So werden Risiken hinsichtlich Fehlfunktionen im Zuge der Entwicklung, die Produktion sowie Montage und den anschließenden Betrieb des Produktes systematisch bewertet und, soweit möglich, ausgeschlossen.

2. Die richtige Vorbereitung einer FMEA

Um die wichtigste Ressource eines Unternehmens, nämlich die Zeit der Experten, effizient nutzen zu können, ist es unerlässlich die Design FMEA oder Prozess FMEA gut vorzubereiten. In Abhängigkeit der Phasen des Produktentstehungsprozesses kommen unterschiedliche Typen von FMEAs zum Tragen. So untergliedert sich die FMEA in System-, Design- und Prozess FMEA. Obwohl diese einzelnen FMEA-Typen in Wechselwirkung zueinanderstehen, sollte man eine Vermischung vermeiden.

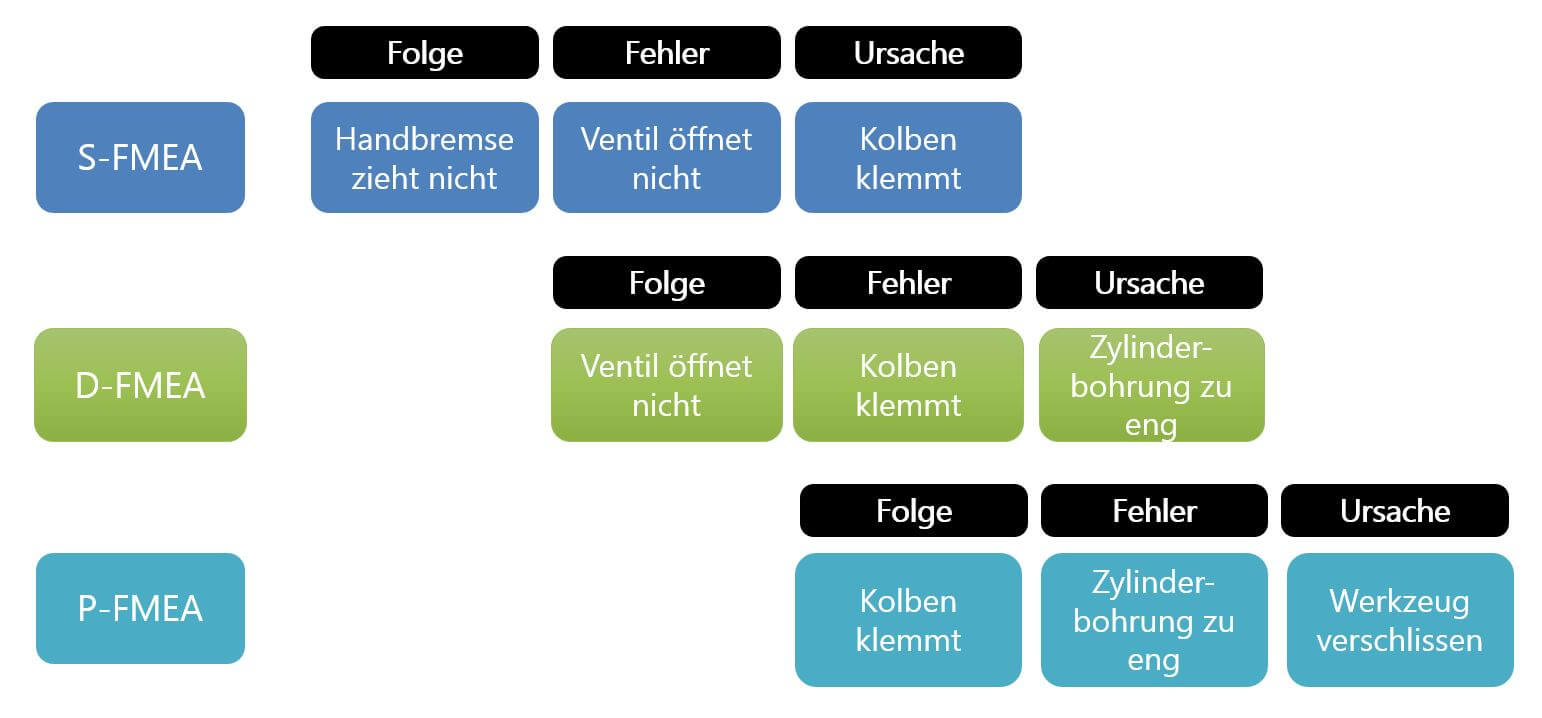

3. FMEA Typen

Es existieren hinsichtlich der Vorgehensweise zwei ausgeprägte Vorgehensmodelle

- FMEA mit dem Fokus der Produktentwicklung

- FMEA mit dem Fokus der Prozessentwicklung (Produktion, Montage)

Daraus abgeleitet haben sich unterschiedlichste Begrifflichkeiten etabliert.

- Für den Fokus der Produktentwicklung: Design-FMEA, D-FMEA, Konstruktions-FMEA, System-FMEA

- Für den Fokus der Prozessentwicklung: Prozess FMEA, P-FMEA

Erwähnenswert ist, dass die System FMEA kein eigenständiges Vorgehensmodell darstellt, sondern eine Ausprägung der Produkt FMEA ist.

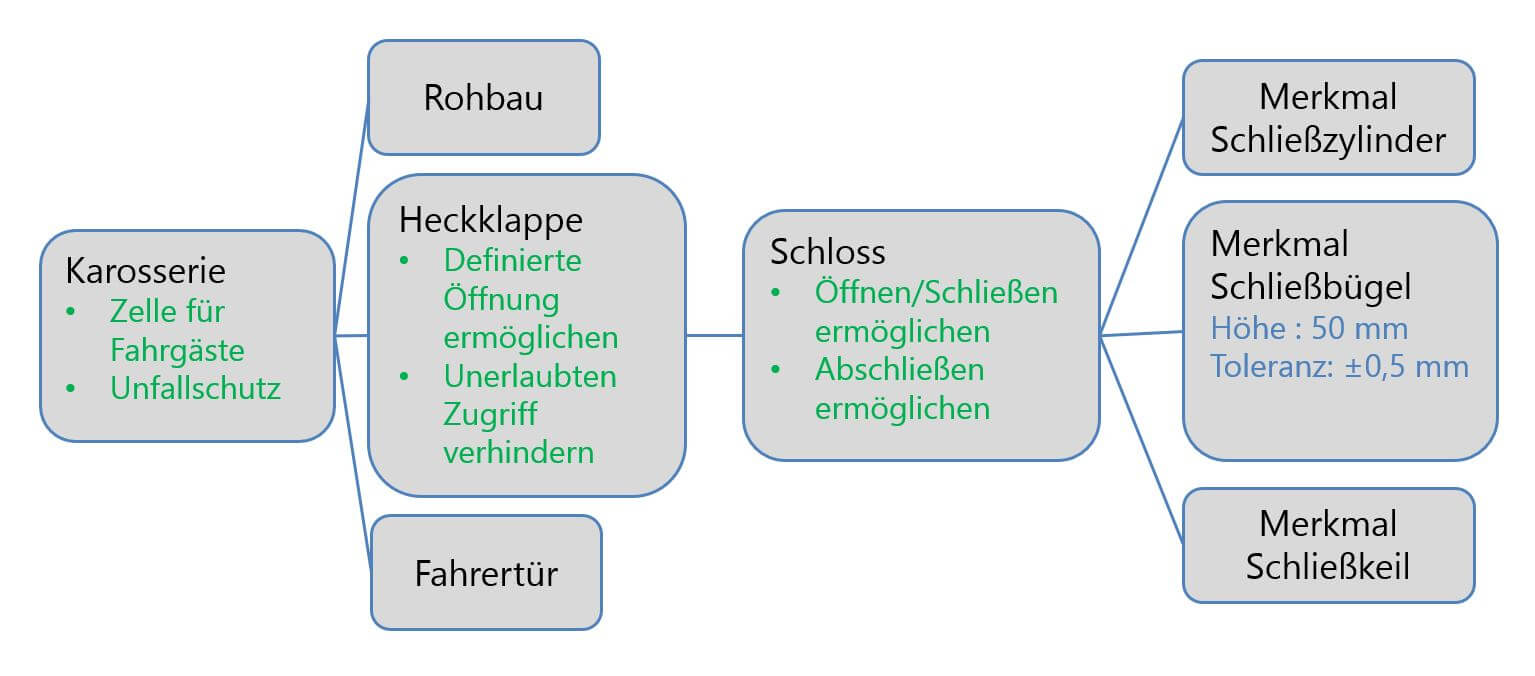

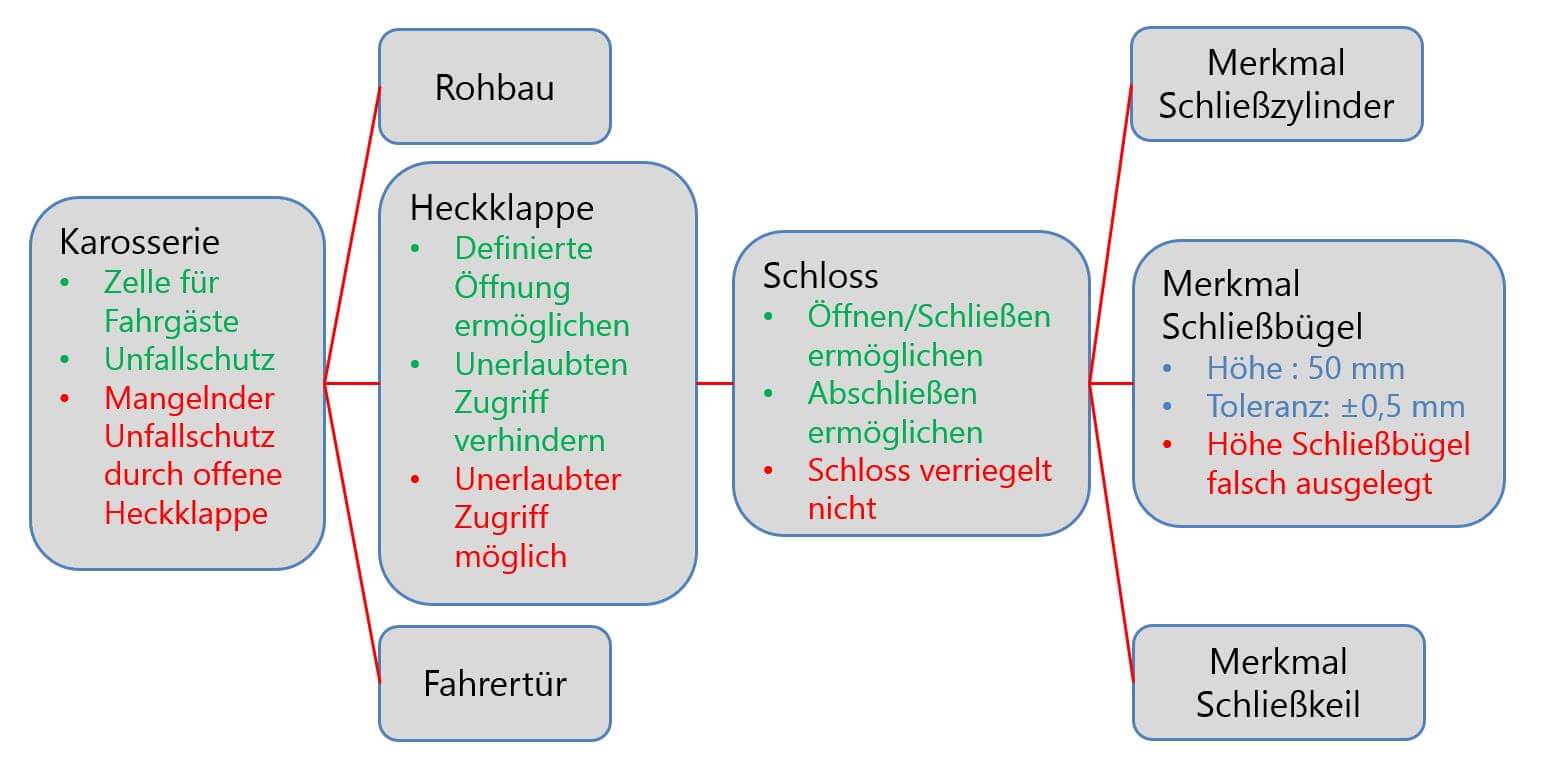

Die nachfolgende Darstellung verdeutlicht mit einem einfachen FMEA Beispiel nochmal die Relation zwischen den einzelnen FMEA-Typen.

4. Die strukturierte Vorgehensweise (Produkt FMEA)

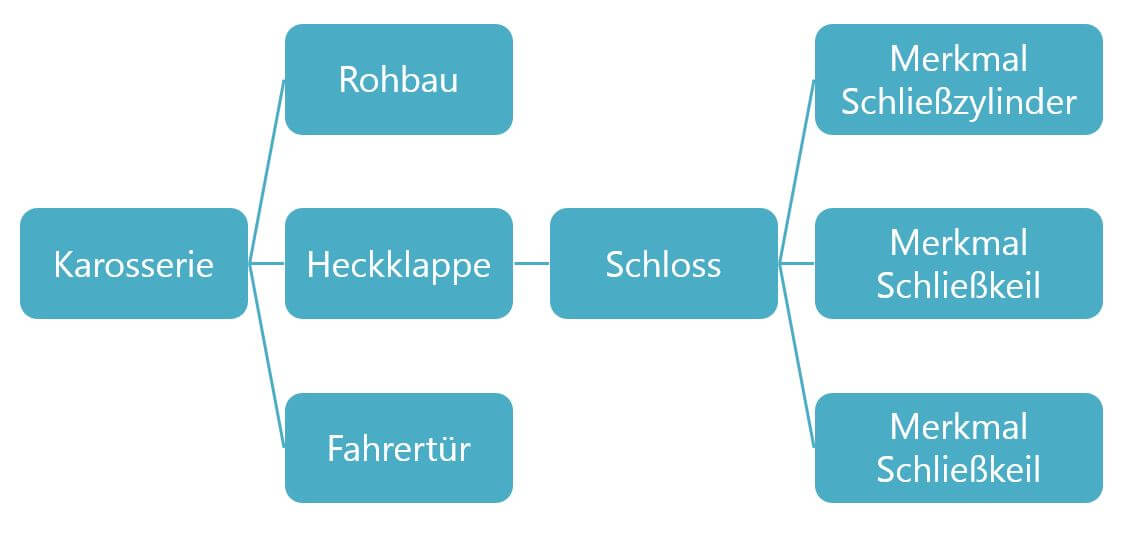

4.1 Die Strukturanalyse

Zur Beschreibung der Systemelemente (SE) und deren strukturellen Zusammenhänge wird eine Strukturanalyse vorgenommen. In Abhängigkeit davon, welche Ziele mit der FMEA verbunden sind, kann der Detaillierungsgrad variieren.

Hinweise zur Strukturanalyse Produkt

- Systemelemente (SE) stehen für Bauteile oder Komponenten, aber auch Baugruppen können als solche bezeichnet werden.

- Systemelemente werden meist funktionsorientiert zugeordnet. Das Gleiche gilt auch für die Systemgrenzen.

- Wichtig: die Systemelemente (SE) sollten nur einmalig in der Struktur Verwendung finden.

- Systemelemente, die durch externe Partner betreut und somit in deren Verantwortung liegen, sollten der Vollständigkeit halber ebenfalls in der Systemstruktur erfasst, aber als „Blackbox“ nicht weiter detailliert werden.

- Die Strukturanalyse ist ein Prozess, der sich in der Praxis schrittweise weiterentwickelt und im Zusammenspiel mit der Funktionsanalyse immer weiter optimiert.

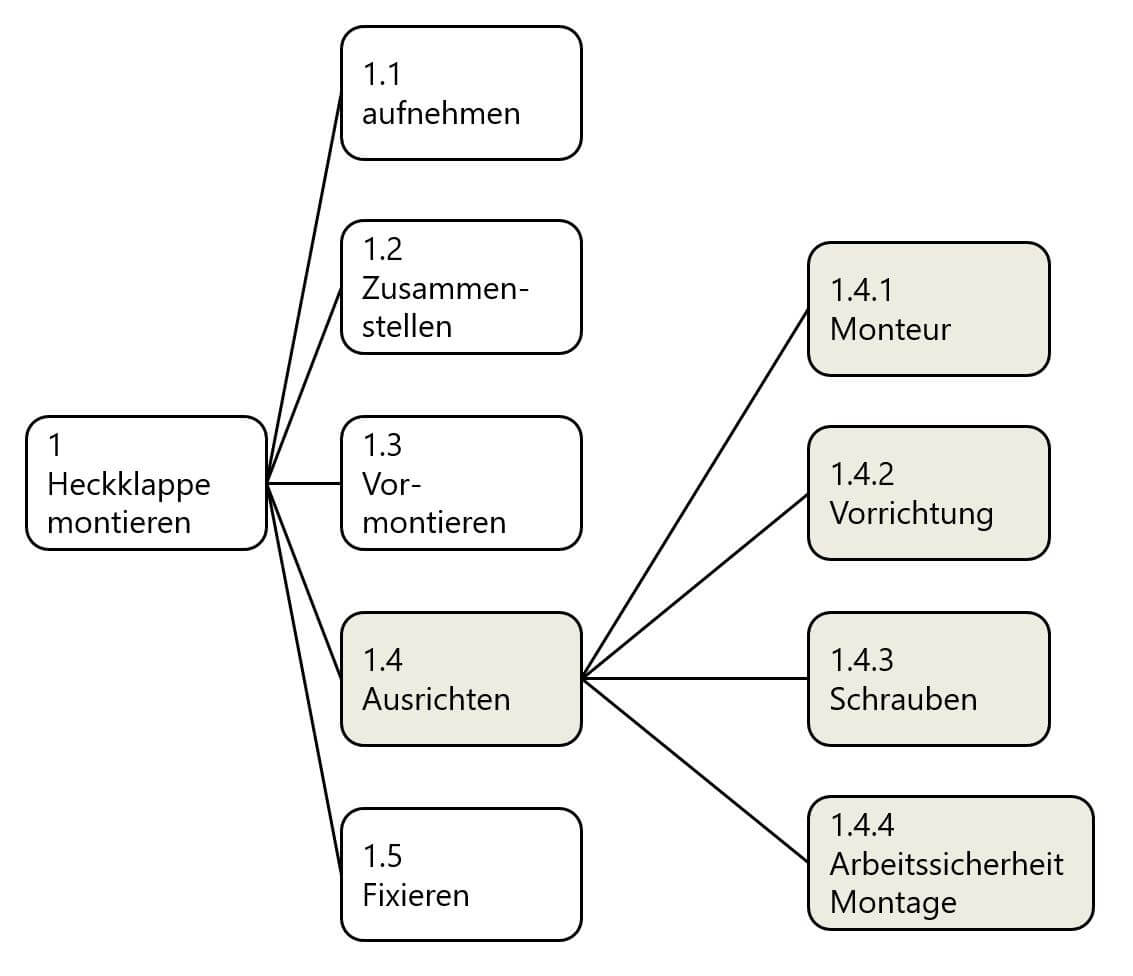

An einen schematischen FMEA Beispiel wird die Strukturanalyse dargestellt

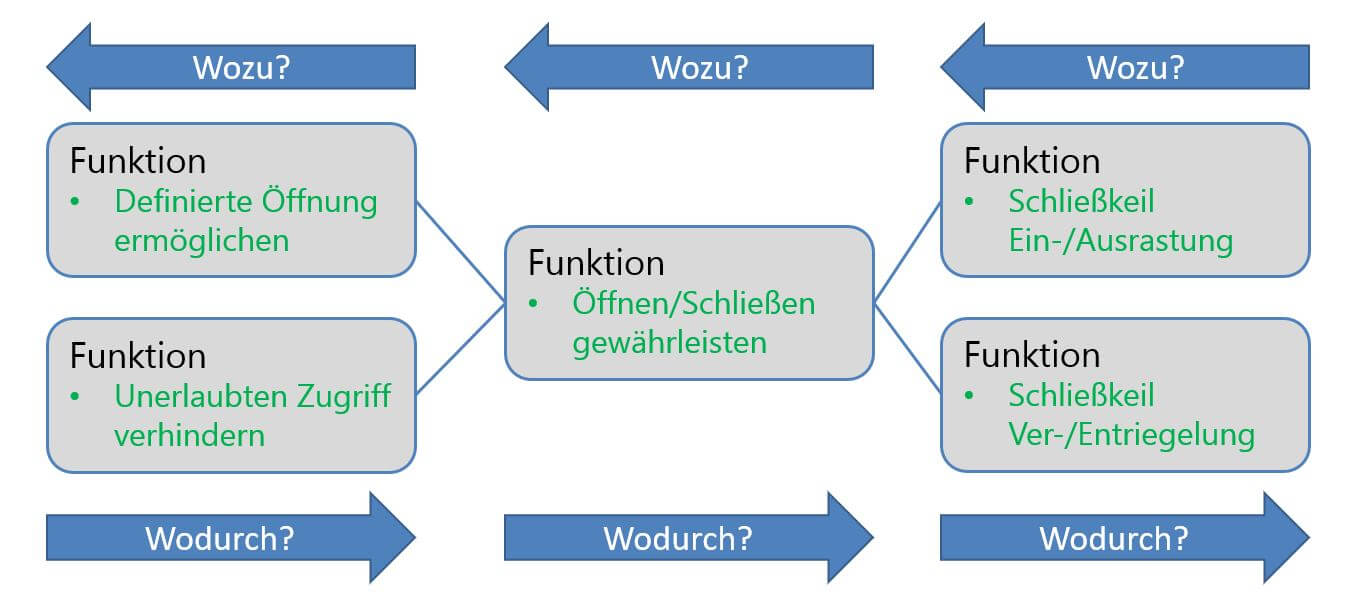

4.2 Die Funktionsanalyse

Ziel der Funktionsanalyse ist, die Funktionen der Systemelemente eindeutig zu beschreiben. Genau wie die Systemelemente stehen auch die Funktionen in Wechselwirkung zueinander. Beschrieben wird dies über verknüpfte Funktionsnetze.

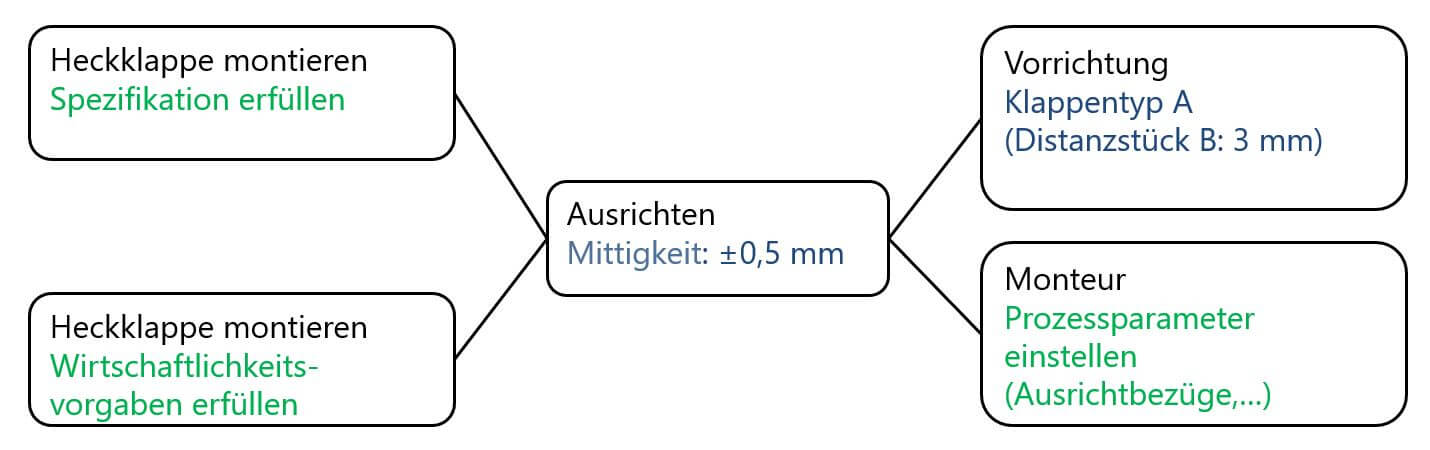

Grafische Darstellung der allgemeinen Zusammenhänge in unserem FMEA Beispiel

Hinweise zur Funktionsanalyse Produkt

- Die Funktionen eines jeden Systemelementes werden basierend auf dem Lasten- bzw. Pflichtenheft exakt beschrieben.

- Eine durchgängige und einheitliche Syntax unterstützt die Verständlichkeit.

- Die Funktionen an den Schnittstellen der Systemelemente sollten als Wandlungsvorgang beschrieben werden (z.B. Dichtung überdrücken).

- Ferner sollten in der Funktionsanalyse die relevanten Betriebszustände (Use Cases) der Analyseobjekte berücksichtigt werden.

- Soweit möglich sollten die Systemelemente als Repräsentant von Produktmerkmalen und nicht als Funktionsträger dargestellt werden.

- Um Lücken im Systemverständnis der Kommunikationsbeteiligten frühestmöglich zu klären und gegebenenfalls zuschließen, sollten die Funktionszusammenhänge in einem Funktionsnetzt dargestellt werden.

FMEA Beispiel für ein Funktionsnetz

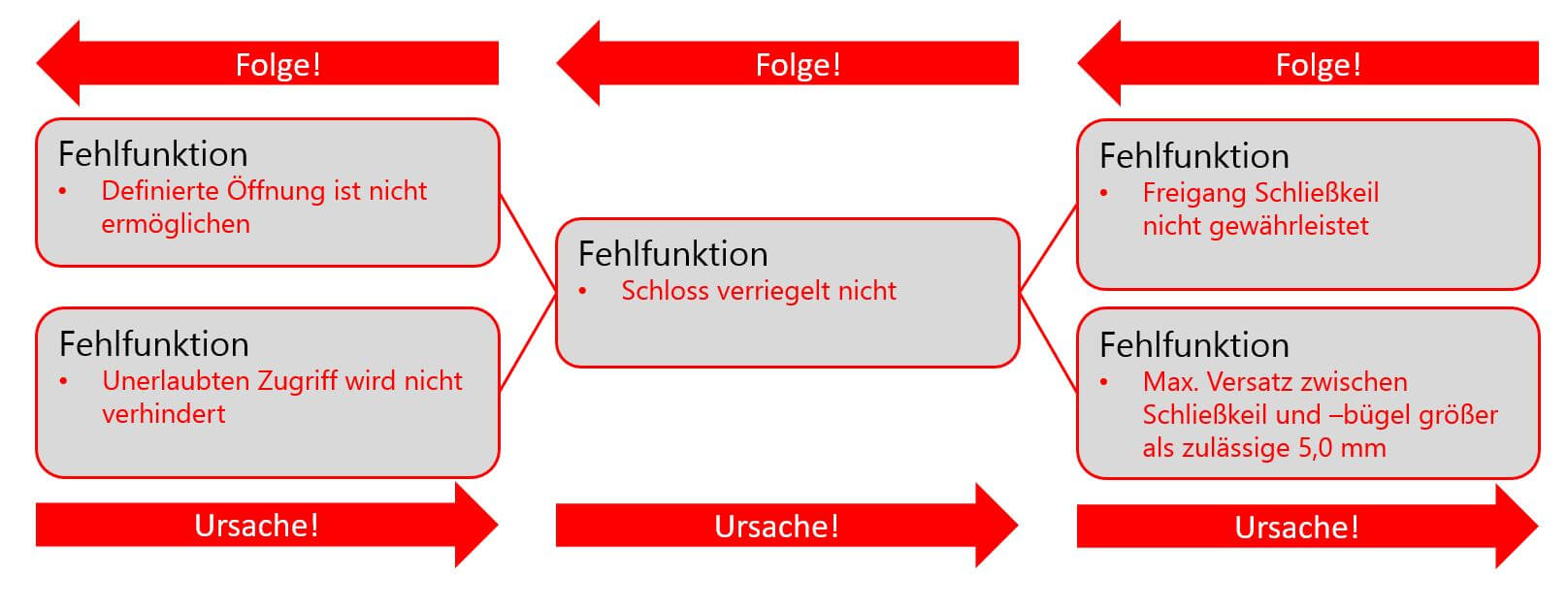

4.2.2 Die Fehlfunktionsanalyse

Im folgenden Schritt wird eine Fehlfunktionsanalyse durchgeführt. Hierbei werden für jedes Systemelement mögliche Fehlfunktionen abgeleitet und diese dann zu einem Fehlernetz verknüpft. Ob eine Fehlfunktion Fehlerfolge, Fehler an sich oder Fehlerursache ist, wird über die Position im Fehlernetz festgelegt. Häufig wird die Durchführung einer FMEA durch spezielle FMEA Software unterstützt. Bei den marktgängigen Softwarelösungen ist es häufig so, dass die Funktionen in grüner Schrift und die Fehlfunktionen in roter Schrift dargestellt werden.

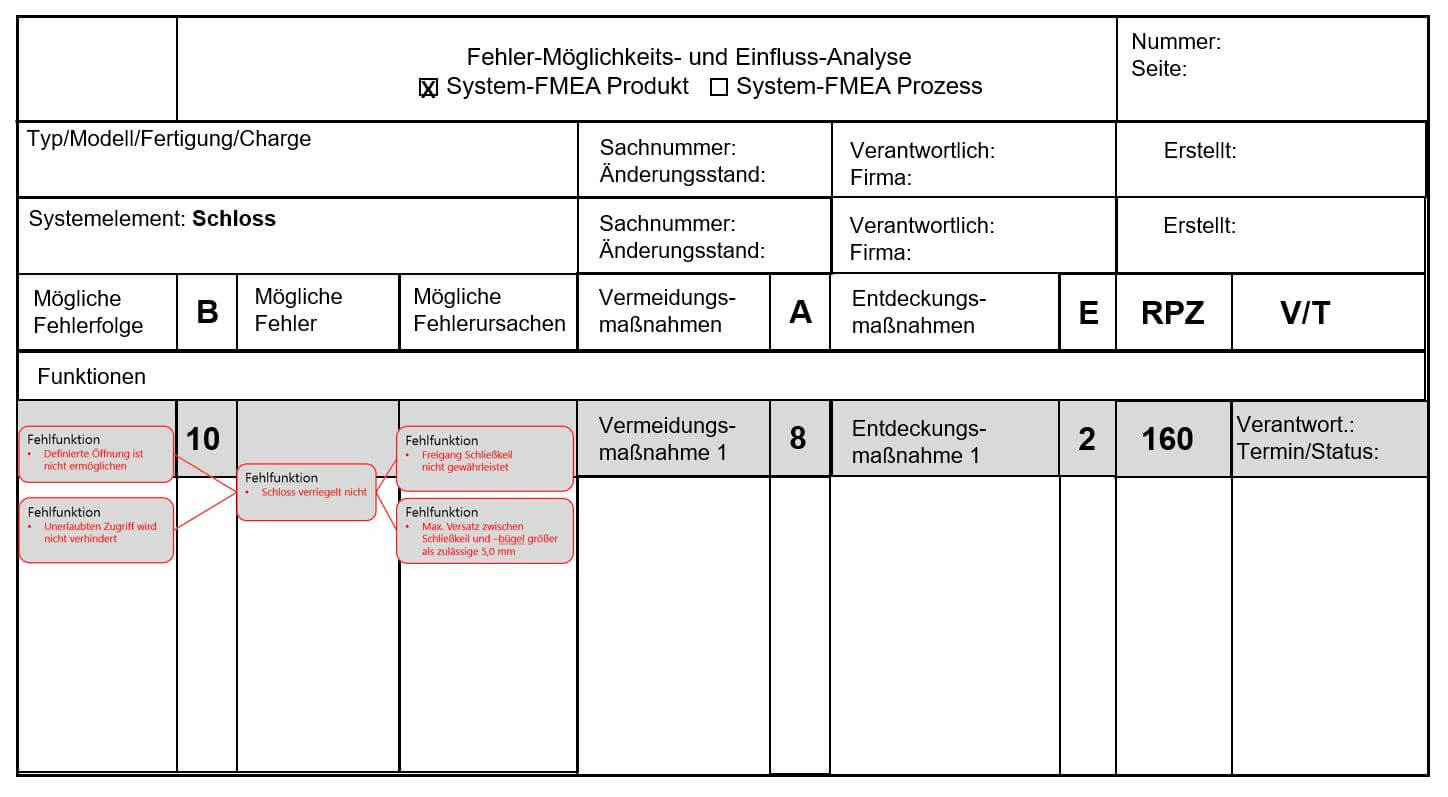

Fehlfunktionsanalyse für das FMEA Beispiel

Hinweise zu Funktionsanalyse Produkt

- Die Fehlfunktionen basieren auf der zuvor durchgeführten Funktionsanalyse. Die einfachste Form der Beschreibung von Fehlfunktionen ist die „Negierung“ von Funktionen.

- Genau wie in der Funktionsanalyse sollten die relevanten Betriebszustände auch in der Fehlfunktionsanalyse berücksichtigt werden.

- Man kann sich die Arbeit erleichtern, wenn sukzessive Fehlerkataloge aufgebaut und als Grundlage für zukünftige FMEAs genutzt werden.

- Selbstverständlich können einzelner Funktionen mehrere Fehlfunktionen zugeordnet werden.

- Die Fehlfunktionen werden in Analogie zu deren Ursache – Fehler – Folgen – Beziehungen zu Fehlernetzen verknüpft.

Die schematische Darstellung eines Fehlernetzes für das FMEA Beispiel

4.2.2 Die Maßnahmenanalyse

Ein wesentlicher Schritt in der FMEA ist die Definition von Entdeckungs- und Vermeidungsmaßnahmen und die Möglichkeit, deren Wirksamkeit bewerten zu können. Es ist unerlässlich, jeder einzelnen Maßnahme entsprechende Verantwortlichkeiten und Termine zuzuordnen. Im Laufe der entwicklungsbegleitenden FMEA wird die Realisierung und Umsetzung der Maßnahmen gelenkt und überwacht. Die Dokumentation der Maßnahmen mit Verantwortlichkeit und Status erfolgt in der Regel über sogenannte Formblätter.

Darstellung eines Formblattes zu dem FMEA Beispiel

Mit den Vermeidungsmaßnahmen werden optimierte System- und Merkmalsauslegungen angestrebt, um somit die Auftretenswahrscheinlichkeit (A) zu reduzieren. Entdeckungsmaßnahmen dagegen zielen auf die Verifizierung der zutreffenden Funktionen ab. Hierbei werden die umgesetzten Vermeidungsmaßnahmen mit einbezogen. Wichtig ist, dass sowohl Vermeidungs- als auch Entdeckungsmaßnahmen konkret und nachprüfbar benannt werden.

In diesen Formblättern werden darüber hinaus Kennzahlen dokumentiert, die die Risikobewertung (besser: Risikoabschätzung) erst ermöglichen. Zunächst wird eine Kennzahl B mit Werten zwischen 1-10 für die Bedeutung von Fehlerfolgen genannt. Des Weiteren gibt es eine Kennzahl A (1-10) für die Auftretenswahrscheinlichkeit der Fehlerursache. Der A-Wert beschreibt eine Art „Qualitätsindex“ der Vermeidungsmaßnahme. Letztlich wird noch eine Kennzahl E (1-10) für die Entdeckbarkeit benannt, dessen Wert seinerseits ein „Qualitätsindex“ für die Entdeckungsmaßnahme darstellt. Allgemein gilt, je höher die Kennzahl ist, desto kritischer wird die Kenngröße bewertet. Die Risikobewertung erfolgt anhand der Risikoprioritätszahl RPZ. Sie bildet sich aus dem Produkt von B, A und E (RPZ = B*A*E). Auch hier kann allgemein gesagt werden, dass je höher die RPZ ist, desto größer ist das Risiko. Welche Werte den einzelnen Kennzahlen zugewiesen werden, ist nirgends formal verbindlich beschrieben. Die Praxis ist dadurch geprägt, dass die Zuordnung unternehmens-, branchen- und länderspezifisch sehr unterschiedlich ausfallen. Es gibt zwar Bestrebungen, Bewertungskataloge, die entsprechende Empfehlungen geben, zu standardisieren und zu harmonisieren. Dennoch wird es immer auch von dem verantwortlichen FMEA-Moderator und den Teilnehmern in den FMEA-Sitzungen abhängen, welche Werte zugeordnet werden.

Darum ist der Hinweis wichtig, dass die Maßnahmenanalyse und somit auch die Risikobewertung in der FMEA keine objektive Bewertung darstellt und womöglich auch in der Zukunft nicht darstellen wird. Die Maßnahmenanalyse ist als subjektive Einschätzung durch (geschulte) Experten zu verstehen.

5. Ergänzendes zur Prozess FMEA

Im Grunde gilt in der Prozess FMEA das Gleiche wie in der Produkt FMEA. Dennoch gibt es einige Unterschiede in der Prozess FMEA, auf die hier hingewiesen werden soll.

5.1 Systemstruktur

Bezüglich der Systemstruktur sollte in der Prozess FMEA in der ersten Ebene die Zielsetzung des Prozesses stehen. In der zweiten Ebene sollte dann die Abfolge der Technologien und Prozessschritte genannt werden. In der dritten und letzten Ebene finden sich dann die Ressourcen (ideal in den Kategorien Mensch, Maschine, Material, Mitwelt, Methode -> die 5 M) wieder.

FMEA Beispiel: Systemstruktur für eine Prozess FMEA

5.2 Funktionsstruktur

Bei der Prozess FMEA werden im Funktionsnetz Funktionen, Produkt- und Prozessmerkmale miteinander verwoben. So stehen in der ersten Ebene die Ziele (Funktionen) des Prozesses. In der zweiten Ebene stehen die erzeugten oder geänderten Produktmerkmale und in der dritten Ebene die Funktionen und Prozessmerkmale.

FMEA Beispiel: Funktionsnetz für eine Prozess FMEA

6. FMEA Software

Grundsätzlich gilt, dass man zur Durchführung der Fehlermöglichkeits- und einflussanalyse keine spezielle FMEA Software benötigt. Als kostengünstigste Lösung für eine FMEA Software bietet sich (wie so häufig) Excel an. Es kann dennoch sinnvoll sein, eine explizite FMEA Software einzusetzen. Die Stärke dieser Tools liegt darin, dass Sie menügesteuerte Funktionen bereithalten, um Systemstrukturen, Funktionsnetze, Fehlernetze schnell und standardisiert abbilden zu können. Ferner bietet eine gute FMEA Software Möglichkeiten, sich Kataloge und Templates aufzubauen, die immer wieder genutzt werden können. Bei entsprechender Eingabe und Pflege der Daten werden die Inhalte der einzelne FMEA-Schritte automatisch untereinander vernetzt, so dass redundante Eingaben entfallen. Das gilt auch für das automatische Ausfüllen der Formblätter innerhalb der FMEA Software. Verschiedene Reports und Auswertungen unterstützen zu dem das Monitoring der FMEA. Um die Dienstleistungen im Bereich Risikomanagement optimal erbringen zu können, setzt casim die FMEA Software IQ-FMEA aus dem Hause APIS ein. Alternativ wird das Produkt SCIO-FMEA aus dem Haus PLATO als FMEA Software eingesetzt.

Quellen: